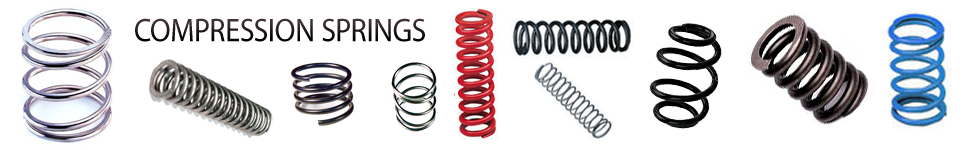

Compression Springs

Compression springs are open-wound helical springs that exert a load or force when compressed. Compression Springs can be coiled as a constant-diameter cylinder, conical, concave, convex, or various combinations.

The ends can be closed & ground, closed but unground, open & unground.

The most common type of end finish is the closed and ground end which is the most stable type as it provides a much greater area for the spring to exert it's force onto.

We are Equipped with the latest in coiling machinery.

Our wire rang is 0.25mm to 10mm in diameter in round. Automatic Coiling: 0.25mm - 3.00mm. Hand Coiling: 3.00mm - 10.00mm

- Wire size - Increasing the wire size of a compression spring will make the spring stronger.

- Diameter - As the diameter of the spring increases the strength (rate) will decrease. The number of active coils is inversely proportional to the rate of a compression spring. This means a large number of coils will result in a fairly weak spring and a small number of coils will give a relatively strong spring. The total coils is dependant on the type of end given to the spring.

- Springs with closed or closed and ground ends will usually have one inactive coil at each end.

- Length - It is usual to specify the free length required. The solid length (fully compressed length) can easily be calculated.

- Rate - The rate (strength) of the spring depends on all of the above factors and can easily be calculated.

- End types - There are four basic types of end finish for compression springs as illustrated above.